6th January, 2026

TILE Manual Handling Considerations (And What Is TILE?)

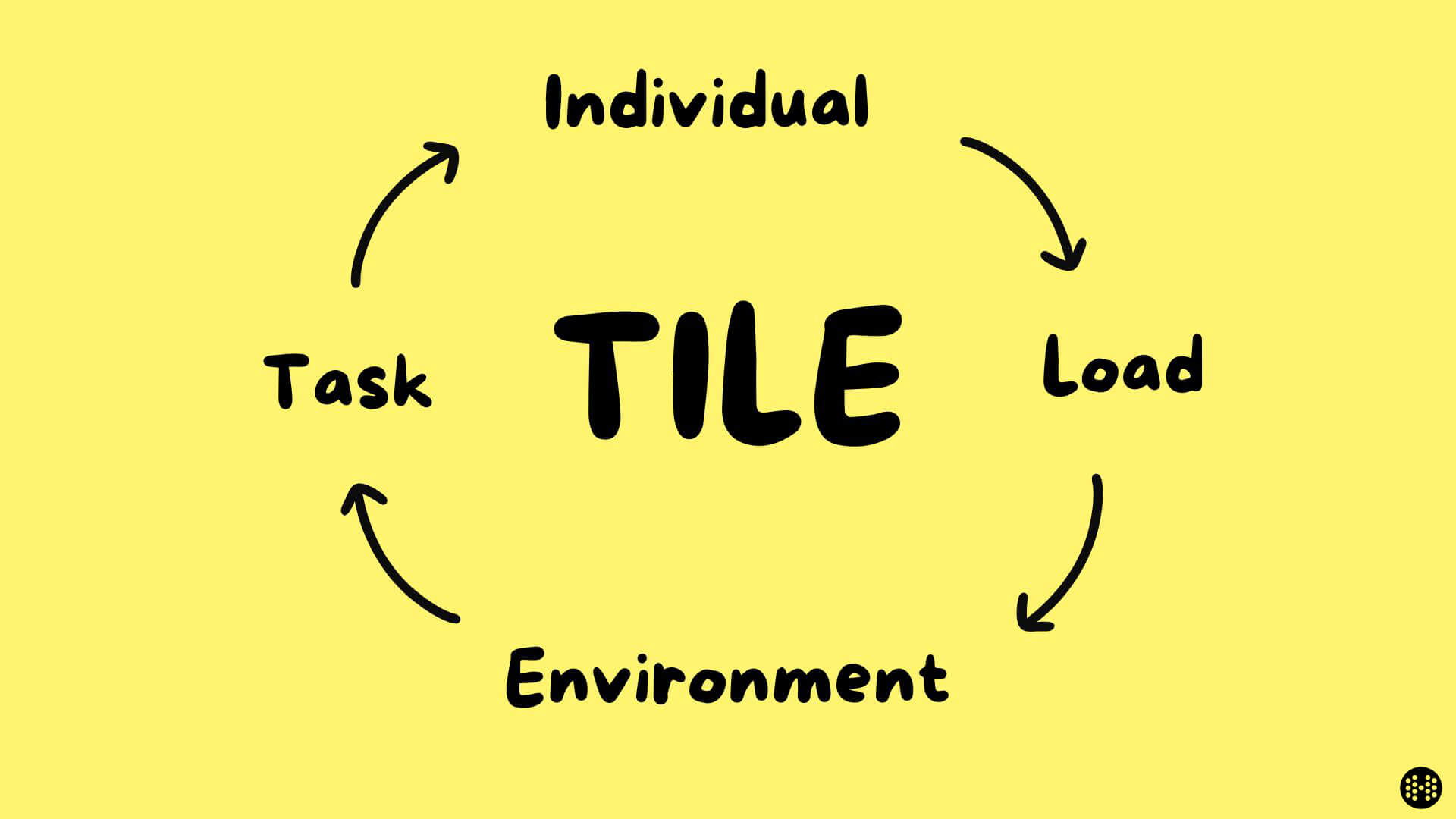

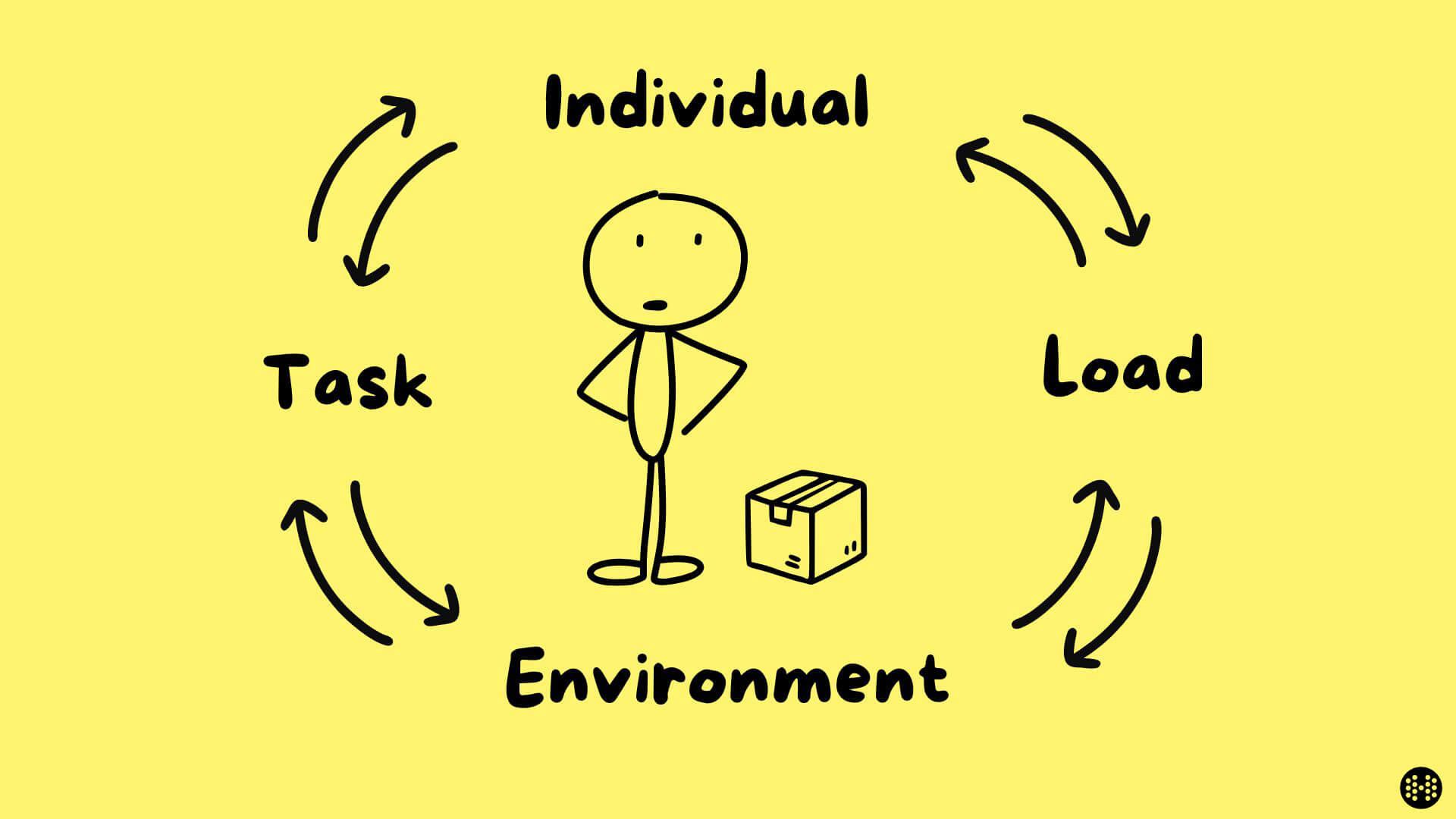

When you are manual handling, you need to know about TILE. But what is TILE? TILE is the four key areas you need to consider when lifting or carrying - Task, Individual, Load, and Environment.

If you get involved with health and safety, you'll quickly realise we have a lot of health and safety acronyms. And manual handling has not escaped this treatment!

In manual handling, you need to think LITE, TILE, and even TILEO.

But what is TILE, and how does it apply to manual handling?

What does TILE stand for in manual handling?

TILE stands for Task, Individual, Load and Environment - these are the four key areas you need to consider when manual handling (including lifting, carrying, pushing, pulling and moving items).

“manual handling operations” means any transporting or supporting of a load (including the lifting, putting down, pushing, pulling, carrying or moving thereof) by hand or by bodily force.

You might also hear people telling you to think LITE with manual handling, and that means the same thing. LITE and TILE are the same letters just arranged in a different order.

And what about TILEO?

That's TILE with an O on the end for Other (or Other factors).

Why the different terms? Well, they each aim to be a quick reminder of the things you should be thinking about before lifting or carrying. Whichever term you use, you need to remember the same four key factors.

- Task

- Individual

- Load

- Environment

TILE was the original manual handling acronym, and remains the most common. It is used as a quick way to remember the four things you need to assess when it comes to manual handling. Task, individual, load, and environment. These four factors cover the risks associated with manual handling activities.

Use our manual handling risk assessment template if you need help assessing TILE considerations at work.

Let's look at the TILE considerations in more detail.

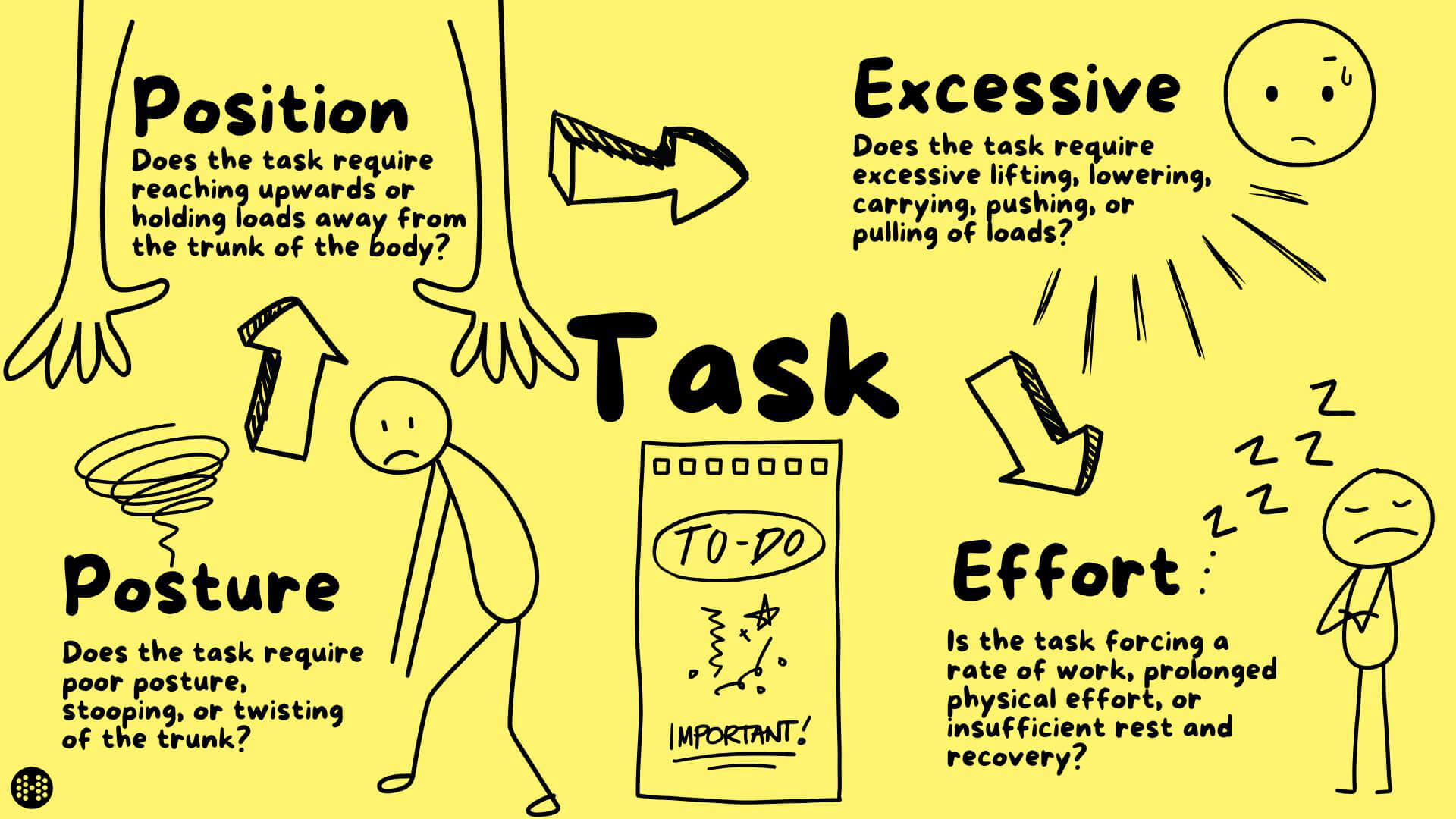

Task

The first factor in TILE is the task. Why do we need to consider the task? Tasks can have an impact on the need to twist or stoop or cause excessive lifting, lowering, or carrying.

Does the task require:

- Twisting of the trunk?

- Stooping or poor posture?

- Reaching upwards?

- Holding or manoeuvring loads away from the trunk of the body?

- Excessive carrying of loads?

- Excessive lifting or lowering?

- Excessive pushing or pulling?

- A process forcing a rate of work?

- Prolonged physical effort?

- Insufficient rest and recovery?

If you answer yes to any of the above questions, then the risk of manual handling injury is increased because of the task.

For the first TILE consideration, think about the task and any improvements that can be made. If the task can be adapted to improve posture, reduce physical effort, and allow for rest periods, you can help reduce the risk of the activity.

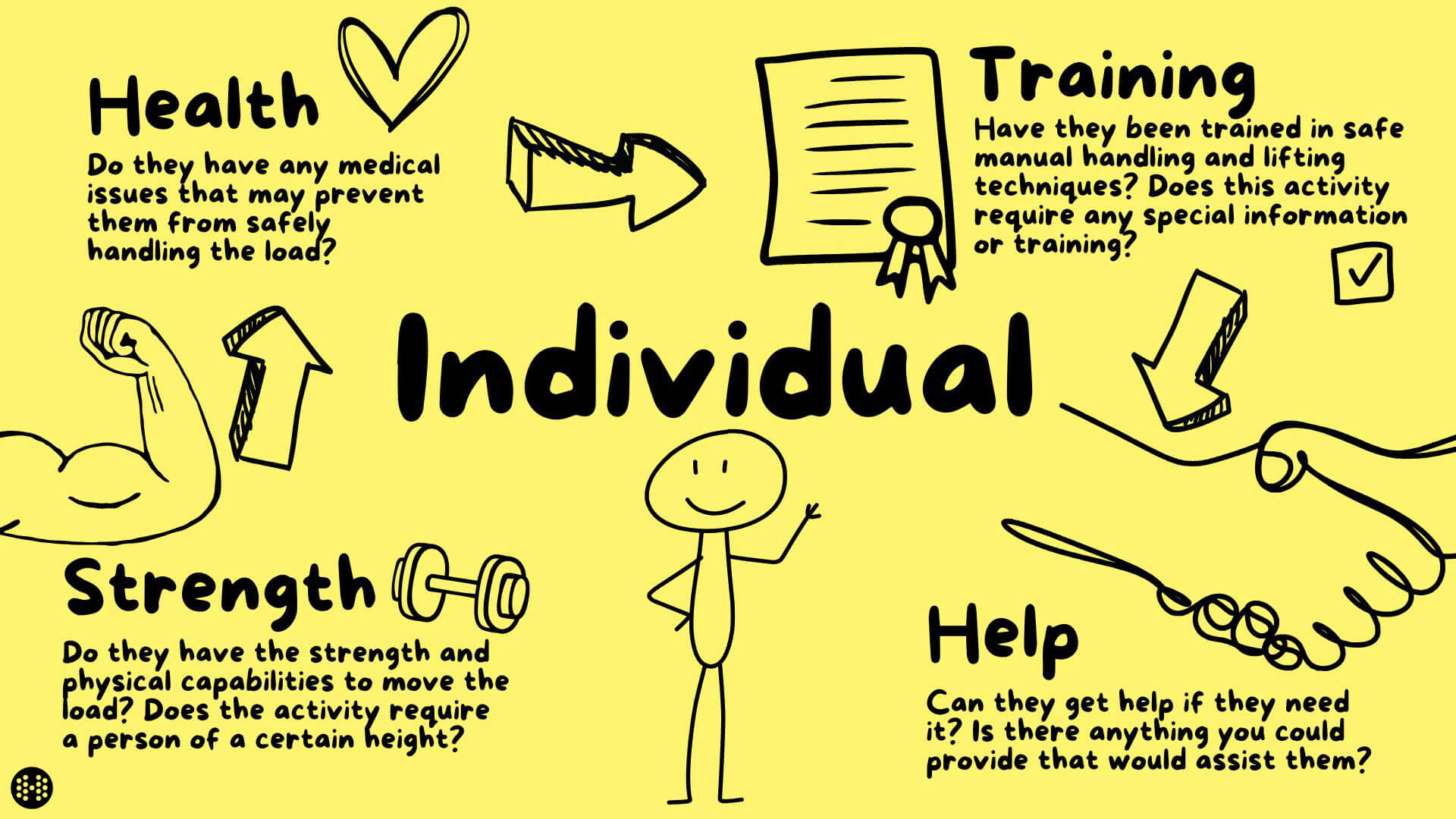

Individual

The second factor to consider is the individual. This is the person who will be doing the manual handling. Their strength and capabilities can have an impact, but so can knowledge of the load and task, along with training and experience.

- Does manual handling require a certain level of strength?

- Does the activity require a person of a certain height?

- Does the individual have a health problem?

- Is the individual pregnant?

- Have they been trained in safe manual handling and lifting techniques?

- Do they know how to handle the load properly?

- Does this activity require any special information or training?

Each manual handling activity is different. While a person may be perfectly capable of lifting and carrying in normal circumstances, you should consider whether there is anything unusual affecting them.

For example, a change in circumstances for the individual, like a health problem, might put them at extra risk. Or the activity might have specific height and strength requirements to consider when selecting individuals for the task.

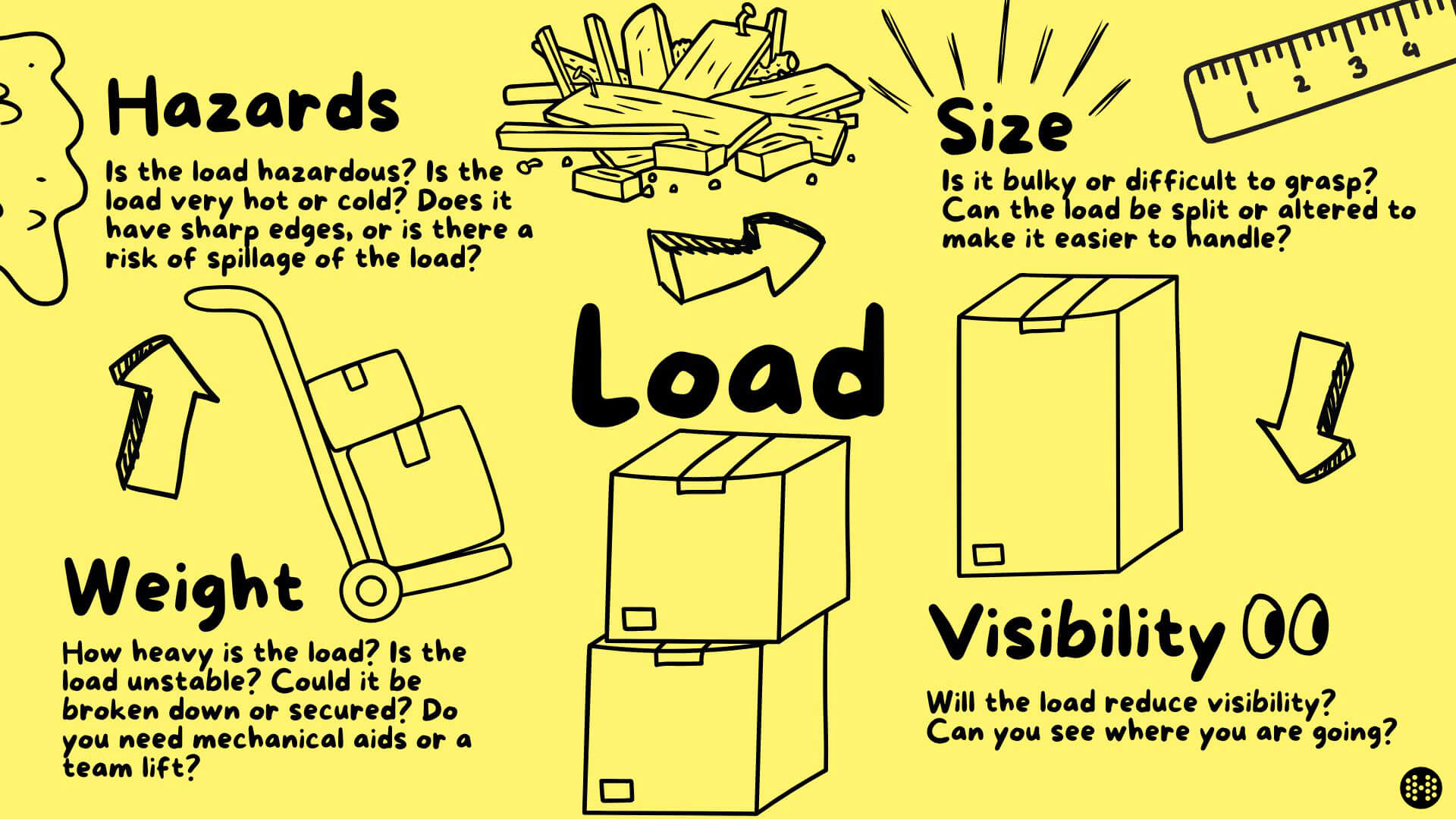

Load

The third consideration in TILE is the load. The load itself can have a big impact on the risk level of the manual handling activity. And you shouldn't only consider weight with manual handling.

How heavy the load is should, of course, be considered, but there are other characteristics of the load that should be assessed.

- Is the load heavy?

- Is the load unstable?

- Is the load hazardous?

- Does it have sharp edges?

- Is there a risk of spillage of the load?

- Is it bulky or difficult to grasp?

- Is the load very hot or cold?

- Will the load reduce visibility?

Answering yes to any of these questions might mean extra measures need to be taken to make the load safe.

If the load can be split or altered to make it easier to handle, then this can also be a good way to reduce risk. Otherwise, for bulky or heavy loads, you could consider mechanical aids or a team lift.

But what about sharp loads that could cut you? Or hot or cold loads that could burn or damage the skin?

You might need wrapping on the load to reduce the risk of contact, and PPE such as protective gloves.

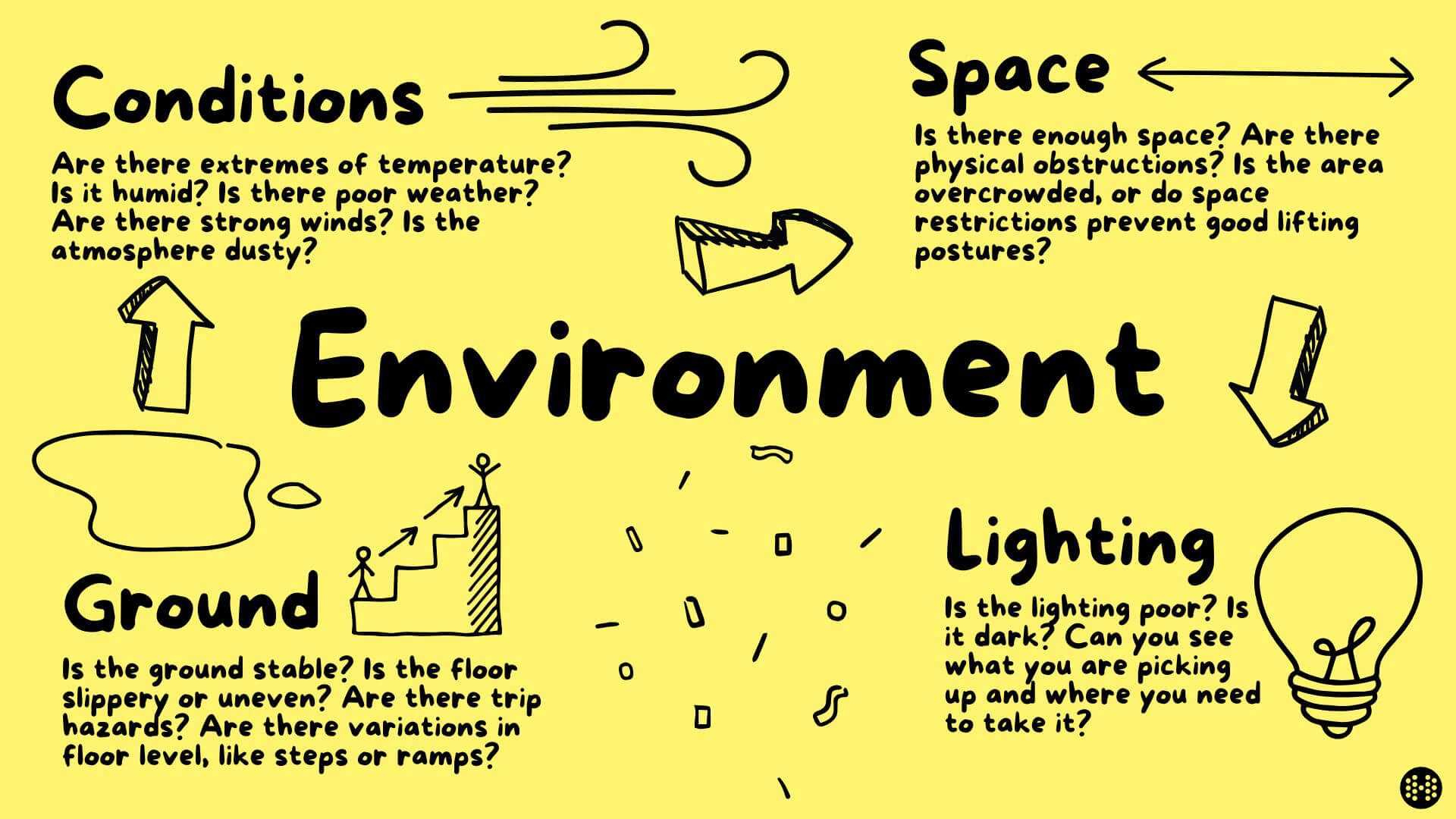

Environment

The fourth and final factor to consider in TILE is the environment. This involved thinking not just about what you are doing, but where you are doing it.

Are you outside or inside? Is the flooring slippery or uneven, creating slip or trip hazards? Are space restrictions preventing good posture? Will other people or vehicles be around?

Where the manual handling will take place can also impact the safety of manual handling operations.

- Is the ground stable?

- Is the floor slippery?

- Is the ground uneven?

- Are there variations in floor level?

- Are there extremes of temperature?

- Is the environment humid?

- Is there enough ventilation?

- Are there strong winds?

- Is the lighting poor?

Planning your route when carrying loads is an important part of reducing the risk when manual handling.

You might not be able to see clearly when you are carrying a load. You might not be able to switch lights on or open doors.

Where manual handling is taking place outside, additional considerations such as wind, rain, ice, and temperature can also affect safety and should be planned for.

Every manual handling operation is different. Remember to carry out a manual handling risk assessment before you start. List any TILE considerations that apply to your activity as hazards, and think about how the risks can be reduced.

Sometimes, you might be able to reduce or avoid manual handling altogether. For example, by using equipment, mechanical aids, or by changing processes and layouts.

Manual handling takes place all the time, but don't get complacent. According to HSE statistics, handling, lifting, and carrying account for 18% of non-fatal injuries. Manual handling is also the biggest cause of musculoskeletal disorders, from which nearly half a million workers are suffering in the UK.

Make sure your team know the risks. Download the free manual handling toolbox talk as a reminder of the TILE considerations.

This article was written by Emma at HASpod. Emma has over 10 years experience in health and safety and BSc (Hons) Construction Management. She is NEBOSH qualified and Tech IOSH.

Can you handle this?

Take our manual handling elearning course and get your certificate today.

Course InfoRecent posts like this...

TILE Manual Handling Considerations (And What Is TILE?)

When you are manual handling, you need to know about TILE. But what is TILE? TILE is the four key areas you need to consider when lifting or carrying - Task, Individual, Load, and Environment.

Read Post

Manual Handling? Think LITE!

Manual handling is the leading cause of musculoskeletal disorders at work. To avoid pulled muscles and painful joints, it's important to know how much you can safely lift, and use good handling techniques. In this blog post, we learn how to think LITE.

Read Post

13 Types Of Manual Handling Injuries And The Hazards That Cause Them

It might surprise you that manual handling is responsible for over 30% of workplace injuries. For something so simple, why so many accidents? Well, it's likely to be because we don't expect anything to go wrong - we lift things all the time.

Read Post